Optiv Lite DCC

Measurement Efficiency

In manufacturing both efficiency and product quality are essential. Hexagon Metrology Optiv Lite DCC is the answer. The system comes with a fully automated 3 axis stage, coupled with the world famous PC-DMIS software, ensuring a quality process using optimum efficiency and reliability.

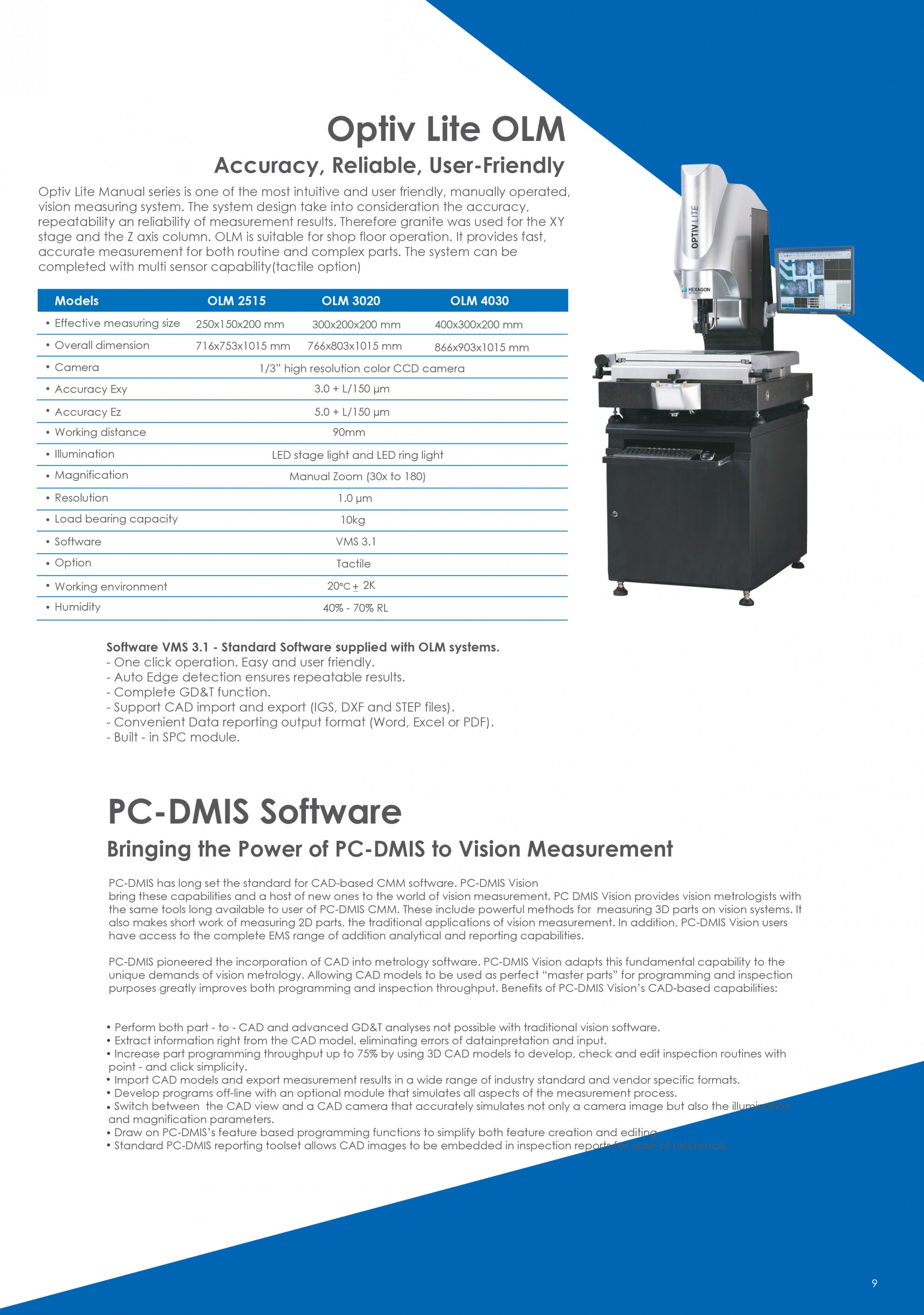

Optiv Lite OLM

Accuracy, Reliable, User-Friendly

Optiv Lite Manual series is one of the most intuitive and user friendly, manually operated, vision measuring system. The system design take into consideration the accuracy, repeatability an reliability of measurement results. Therefore granite was used for the XY

stage and the Z axis column. OLM is suitable for shop floor operation. It provides fast, accurate measurement for both routine and complex parts. The system can be completed with multi sensor capability(tactile option).

Compact, robust design

OPTIV Lite 3.2.2 is a space-saving benchtop CMM with mechanical linear guides on all axes, a solid machine base and fixed bridge in granite and an optional base frame. The machine’s quality design is based on proven concepts from higher-level products within the OPTIV range, enabling optimised and dependable measurement performance in a wide temperature range. This makes the OPTIV Lite 3.2.2 suited for both final inspection of finished products and for quick process control close to tough production environments.

Vision and tactile measurement

The machine is offered in two standard configurations: the basic version is designed with Hexagon’s programmable 6x motorised zoom optics, a high resolution digital colour camera and a variable illumination in the form of a coaxial LED top light, telecentric LED back light and multi-segment LED ring light for high contrast illumination of complex surfaces and edges. The advanced multisensor model comes equipped with an additional touch-trigger probe. The system’s application flexibility can be further increased with a laser triangulation sensor which is available as an option. An optional rotary indexing table can be used to make harder to reach features easier to access.

Easy-to-use software

PC-DMIS metrology software comes as standard with OPTIV Lite 3.2.2, and users can increase operational simplicity with Inspect, a stand-alone application that allows production-level operators to easily execute measurement routines using a standard, user-friendly interface. Available as an option, Inspect Slideshow helps production-level CMM operators to immediately identify and resolve manufacturing defects using graphical real-time feedback on custom key dimensions. And Inspect Pallet offers the ability to configure a pallet for measuring a batch of parts with ease.

Connectivity to Hexagon’s smart technologies

OPTIV Lite 3.2.2 aims above entry-level standards in automated dimensional inspection by connecting with Hexagon’s innovative end-to-end manufacturing solutions for ease of operation (Inspect), remote system and environmental monitoring (HxGN SFx | Asset Management, PULSE), automated quality data management (Q-DAS) and automation integration (I/O kits). Full accessibility to these smart technologies allows customers to keep pace with the rapid development towards the Smart Factory and helps them optimise their production cycle by eliminating bottlenecks and inefficiencies in associated quality control processes.

Software VMS 3.1 - Standard Software supplied with OLM systems.

- One click operation. Easy and user friendly.

- Auto Edge detection ensures repeatable results.

- Complete GD&T function.

- Support CAD import and export (IGS, DXF and STEP files).

- Convenient Data reporting output format (Word, Excel or PDF).

- Built - in SPC module.

PC-DMIS Software

Bringing the Power of PC-DMIS to Vision Measurement

- C-DMIS has long set the standard for CAD-based CMM software. PC-DMIS Vision bring these capabilities and a host of new ones to the world of vision measurement. PC DMIS Vision provides vision metrologists with the same tools long available to user of PC-DMIS CMM. These include powerful methods for measuring 3D parts on vision systems. It also makes short work of measuring 2D parts, the traditional applications of vision measurement. In addition, PC-DMIS Vision users have access to the complete EMS range of addition analytical and reporting capabilities.

- PC-DMIS pioneered the incorporation of CAD into metrology software. PC-DMIS Vision adapts this fundamental capability to the unique demands of vision metrology. Allowing CAD models to be used as perfect “master parts” for programming and inspection purposes greatly improves both programming and inspection throughput. Benefits of PC-DMIS Vision’s CAD-based capabilities:

- Perform both part - to - CAD and advanced GD&T analyses not possible with traditional vision software.

- Extract information right from the CAD model, eliminating errors of datainpretation and input.

- Increase part programming throughput up to 75% by using 3D CAD models to develop, check and edit inspection routines with point - and click simplicity.

- Import CAD models and export measurement results in a wide range of industry standard and vendor specific formats.

- Develop programs off-line with an optional module that simulates all aspects of the measurement process.

- Switch between the CAD view and a CAD camera that accurately simulates not only a camera image but also the illumination and magnification parameters.

- Draw on PC-DMIS’s feature based programming functions to simplify both feature creation and editing.

- Standard PC-DMIS reporting toolset allows CAD images to be embedded in inspection reports for ease of reference.

Digigate Technology

We, Digigate Technology Group Provides Not just a Measuring Instrument But a Complete Package of Metrology and Automation Services.

Service networks are strategically located throughout the Asia-Pacific region. With these strong support networks which enable us to enhance in monitoring timeline to provide rapid support to our customer. DIGIGATE also has a professional group of people attained with hignest degree of experience and quality service attitude to provide application solution support and meet all your metrology and automation needs.

Sale & Services

DIGIGATE marketing and service networks are strategically located throughout the Asia-Pacific region. With these strong service support networks which enable us to enhance in monitoring timeline to provide rapid support to our customer. DIGIGATE also has a professional group of people attained with hignest degree of metrology experience and quality service attitude to provide application solution support and meet all your metrology needs